A Dockside Evening, a Shift in Thinking

I once watched a night shift at a cross-dock where everything looked smooth until the rush hit. The lifting robot rolled in like a quiet teammate, not a showboat. Numbers tell the story: load cycle times drop by a fifth when routes are stable, and strain injuries dip in the same range when bending and twisting go down. But here’s the real question: if the job is mostly repeatable, why are we still relying on stop‑and‑go human judgment for every lift, every hour? (It’s a fair ask.) I’ve seen forklift fleets idle for minutes between picks—funny how that works, right?—and those minutes add up, day after day.

Think about a busy aisle at 5 p.m., a truck at the dock, and three pallets that need cross-stacking before dispatch. The operators know the dance, but traffic, battery swaps, and small delays steal time. A machine built for pattern work won’t complain about shift change or a tight corner. It will do the next safe move, then the next. So, what stops us from letting automation shoulder more of the routine? Let’s walk through the less obvious sticking points, then compare what the new tools actually change. Onward to causes, not just symptoms.

The Hidden Friction in Traditional Lifts

Why do legacy fixes fall short?

Old fixes—more signage, stricter routes, extra supervision—try to shape human behavior in a maze of variables. With heavy lifting robots, we remove parts of the maze itself. Legacy forklifts hinge on driver skill, fatigue, and line‑of‑sight. They also waste energy idling; the stop‑start cycle is rough on batteries and power converters. Even when you add sensors to trucks, you still juggle human reaction time and inconsistent approach speeds. Meanwhile, modern platforms fuse SLAM with inertial measurement units (IMUs) and torque sensors to hold steady, predictable motion in tight aisles. That steadiness cuts micro‑delays you don’t even notice. Look, it’s simpler than you think: when micro‑delays fade, throughput rises without heroics.

Then there’s the control stack. Traditional fixes bolt on a PLC rule or a new camera, but decision logic remains brittle. Edge computing nodes on the robot mean path planning adapts in real time, not after a human radios the office. When a pallet is skewed, the robot adjusts fork alignment and lift profile within the same loop—no pause, no debate. The result is not flashy; it’s a drumbeat. Small, safe corrections at machine speed produce the effect that managers usually chase with more staff and tighter deadlines. That’s the deeper layer: old tools try to manage variance; new ones absorb it.

Principles That Push the Field Forward

What’s Next

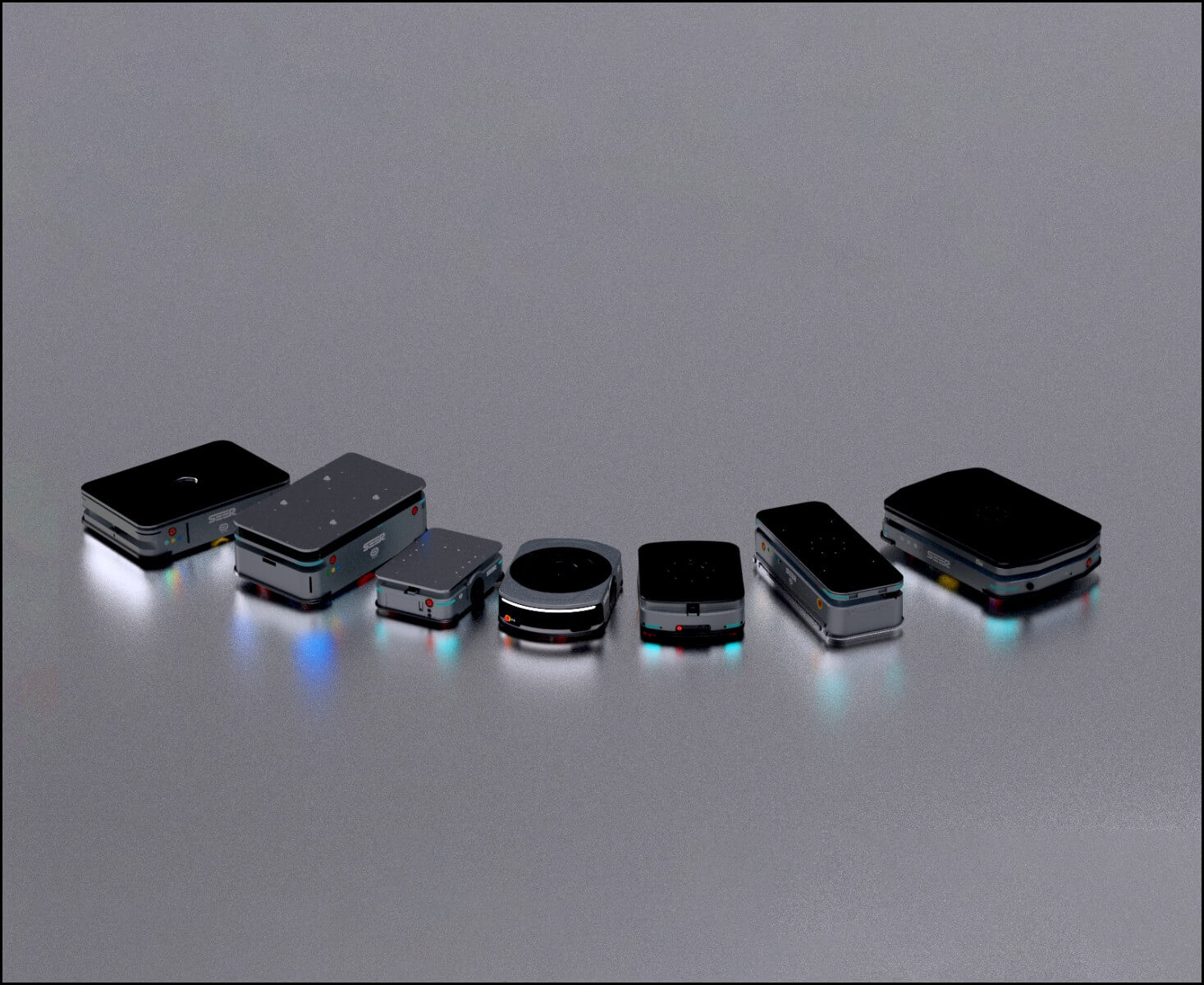

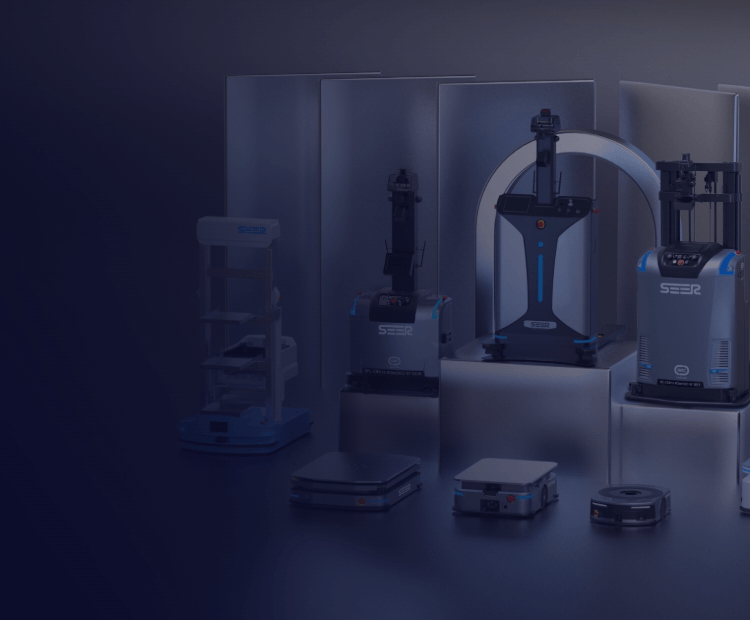

From here, the comparison sharpens. The newer stack uses three ideas in concert: local intelligence, shared context, and measured intent. Local intelligence lives on the unit—pathing, lift profiles, and obstacle handling run right there. Shared context flows through fleet orchestration, where missions, priorities, and dock timing get balanced across robots and people. Measured intent shows up in how the machine declares its next move, with signals that line workers can read at a glance. Add a digital twin for layout tests, and you get faster changeover without parking a single truck. In this model, heavy lifting robots become steady partners, not gadgets to babysit (a big shift).

It’s not just control theory. Practical gains land in power use, service windows, and safety. Battery management systems stretch runtime by smoothing peaks; predictive maintenance flags a drifting wheel motor before it strands a pallet; and modular drives simplify swaps when something does fail—funny how the simplest swap saves the most time, right? For a fair comparison, stack the new against the old on clean terms. First, mission success rate under congestion. Second, error recovery time when a load is off-center. Third, integration depth: does it speak WMS tasks natively or via fragile middleware? If those three look strong, you’ve got a path to steady gains without drama. And yes, keep it human: the best systems make floor traffic calmer and choices clearer, shift after shift.

So the takeaway is straightforward: traditional fixes discipline people; modern platforms reduce the need for discipline. Measure outcomes where it counts and choose accordingly. My closing advice—evaluate three metrics before you commit: 1) time-to-recover from a blocked path, 2) lift accuracy under mixed pallet types, and 3) fleet throughput during peak hour with safety buffers intact. If a vendor can show repeatable numbers there, you’ll know you’re buying time, not just equipment. Shared in good faith, from long hours and a lot of scuffed floor paint. SEER Robotics